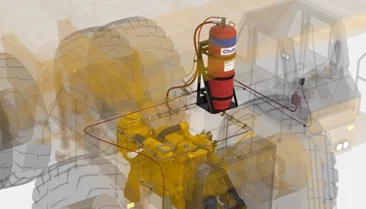

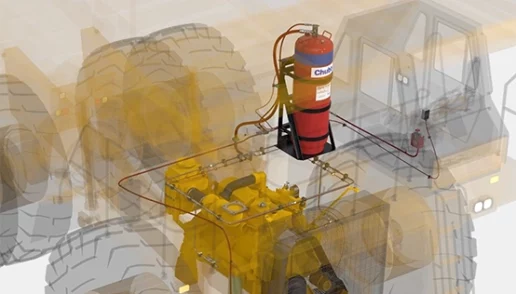

Heat, flammable liquids and electrical components in an enclosed engine compartment can pose a significant fire risk. An accident, ruptured fuel or hydraulic line or even a faulty part can result in a serious emergency.

PEFS Systems

Pre-engineered foam spray (PEFS) fire protection systems are versatile, cost effective and designed to handle extreme operating conditions.

Strategically positioned spray nozzles achieve fast and effective fire suppression by directing high velocity foam spray onto a pre-determined fire hazard area.

Introducing our new system

Highly effective and superior coverage for your fire hazards.

Uses a specifically designed nozzle that both agitates and aerates the fluorine free foam solution.

Designed to work effectively and consistently with a “Newtonian” F3 that does not require mixing before use.

Maintenance Manual

PEFS C6 Maintenance Manual v1.0 Oct 2018

Service Bulletins

TB201801 Change to PEFS Cylinder Assemblies

TB201802 Improvement to PEFS Brackets

TB201901 PEFS – Pressure Monitoring changes

TB201902 PEFS – F3 Nozzle Cap Replacement

TB201903 PEFS – F3 Foam Mixing

TB201904 PEFS – F3 Steel Fittings

TB202001 PEFS – LOP Valve Actuation Bypass

TB202002 PEFS LOP Valves manufactured before 2012

TB202003 PEFS LOP Valve Actuation Bypass – Design change

TB202101 PEFS – New Fittings 12-08-2021

TB202102 PEFS LOP Valve Actuation Bypass – New punch mark

TB202103 PEFS – F3 Steel Fittings – Important safety update

| Description | Version | Type | Link |

| VS-MKII Install Manual | 1.1 | Manual | VS-MKII Install Manual.pdf |

| FSM-ES and FSM-S Fire System Monitoring Panels Manual | 1.2 | Manual | FSM-ES and FSM-S Fire System Monitoring Panels Manual.pdf |

| FSM-ES Setup Guide | 2 | Manual | FSM-ES Setup Guide V2.pdf |